AI data center is an AI training processing and storage center for a large amount of important data, the power distribution system and PDU in the cabinet of the AI data center are significantly different from other types of distribution cabinets, a large number of GPUs in the cabinet superimposed on the power consumption and heat generation is also extremely large, the power density of power consumption has risen significantly, the power of a single cabinet has jumped from the traditional 4-6kW to 20-40kW, and the PDU plug socket wiring in the cabinet is significantly more, which increases the hidden danger risk of the safe operation of the AI data center. Especially in the data centers of some key AI applications, the data loss caused by sudden failures is far greater than the value of the distribution PDU line.

It is recommended to install a red array NKTEVA6 the PDU line of the data center power distribution system for real-time infrared detection. Hidden dangers such as loose plugs or over-temperature operation of equipment can be found in time, and maintenance can be reasonably arranged to improve the reliability of equipment operation, ensure the operation quality of equipment, reduce sudden failures, and reduce equipment failure rate. In addition, it is also recommended to conduct manual and fine infrared detection of the PDU line of the data center distribution system to prevent faults and issue a report every year.

In addition, when accepting the newly built AI data center, the third-party testing agency shall conduct testing, verification and evaluation of the decoration, environment, electrical, HVAC, water supply and drainage, weak current, fire protection and other subsystems of the computer room in accordance with the national standard GB50174 "Data Center Design Code", GB50462 "Data Center Infrastructure Construction and Acceptance Code", and CQC1324"Data Center Site Infrastructure Certification Technical Specification", and issue a third-party test report. These include infrared thermal imaging to scan electrical faults.

The newly built AI data center needs to carry out electrical tests that need to be accepted during acceptance, such as insulation test, withstand voltage test, overcurrent protection test, etc., but for the cable and wire joints of these projects are loose and heated, the above tests may not be tested.

This is due to the fact that the contact resistance of the poor contact joint is relatively large, and most of the energy is lost at the poor contact joint, even when the operating current is relatively small, it will heat abnormally, and even the heating temperature is relatively high.

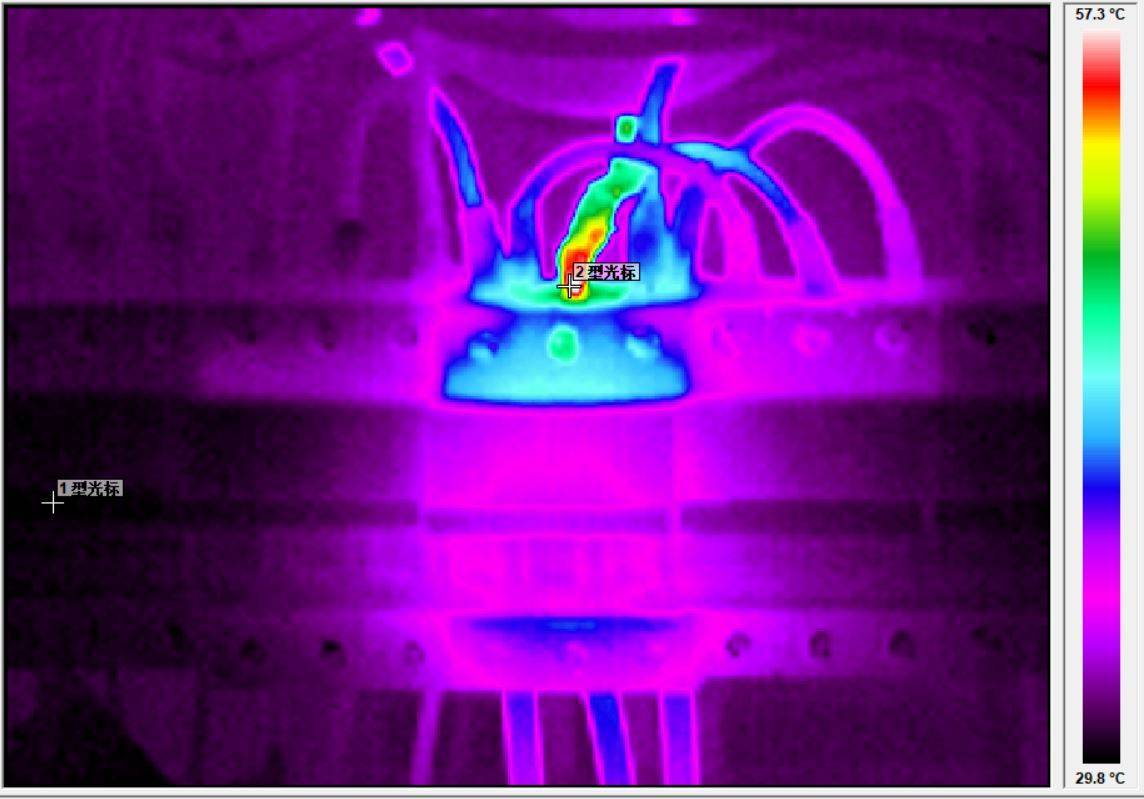

The picture below is a thermal imaging detection diagram of the heat of the two-in-one poor contact connector of the relay in the cabinet

Distribution box running current very small abnormal heat poor contact terminal lead thermal imaging detection diagram

Thermal images of heat in these poorly contacted joints all share common characteristics

That is, the heat distribution of abnormal heat generation is the highest temperature at the bad joint.

Its upper power cord is hotter on the contrary, and its back-end outlet is also colder

Other normal wiring with adjacent current and voltage is basically the same, and the temperature is normal

General electrical test and observation methods are not easy to find

Therefore, infrared thermal imaging testing needs to be applied to the completion acceptance inspection of new construction projects. For electrical equipment that has just been put into operation and is still under warranty, infrared thermal imaging testing can detect defects or hidden dangers such as potential poor contact or excessive use of wires and cables during the installation process as early as possible, and can allow the construction unit to rectify in time and lay a solid foundation for the long-term stable operation of the equipment.