The hidden danger investigation service of fire control of infrared thermal imaging detection Introduction With the development of economic construction and the improvement of people's living standard, the increasing number of various electrical equipments, there exist many problems, the quality of electrical products, engineering design and construction of the installation and operation management etc., the final concentration for the existence of some electrical hazards and risks of electrical fire electrical equipment and wiring operation, easily lead to fire, cause heavy property losses and heavy casualties. Therefore, the fire safety inspection, electrical safety testing of electrical equipment and wiring, electrical fire hazard exists to determine the location and severity, to take timely measures to eliminate hidden dangers, can effectively prevent and reduce the occurrence of electrical fire. An important means of infrared detection technology is the electrical safety testing.

Fire hazard investigation service infrared thermal imaging detection

Brief introduction

With the development of economic construction and the improvement of people's living standards, the number of various electrical equipment is increasing day by day, and there are many problems in the quality of electrical products, engineering design, construction, installation and operation management, etc., which are ultimately concentrated in the existence of some electrical accidents and electrical fire hazards in the operation of electrical equipment and lines, which are very easy to cause fires, resulting in heavy property losses and major casualties.

Therefore, in the fire safety inspection, the electrical safety inspection of electrical equipment and lines, the existence and severity of electrical fire hazards are determined, and timely measures are taken to eliminate hidden dangers, which can effectively prevent and reduce the occurrence of electrical fires. Infrared detection technology is an important means of electrical safety detection.

Infrared detection technology is the basis for the development of a new comprehensive technology in Infrared Physics, electronics and computers as infrared light, it is widely used in many fields of military, electric power, petrochemical, metallurgy, medicine etc.. In recent years, in the electrical fire safety inspection, found that the electrical fire hazards, prevention and reduction of electrical fire accidents have achieved remarkable results.

The principle of 1 Infrared Detection Technology

Infrared light is an electromagnetic wave, the wavelength range of 0.76 ~ 1000 m, are no longer visible. Any temperature above absolute zero (273.15 C) object, is constantly emitting infrared radiation. According to Stephen Boltzmann's law, temperature of T objects, radiation power emitted per unit area is

P=εσT4 (1)

Where:

P——radiated power per unit area, (W); Unit area radiation power

ε – surface emissivity of the object; Object surface emissivity;

σ - Stephan-Boltzmann constant, whose value is 5.673×10-8W/(m2K4);

Stephen Boltzmann constant, the value for the

T – surface temperature of the object, (K). The surface temperature,

From the type, surface temperature higher, radiation power per unit area of the greater. When the surface temperature of known objects and its emission rate, the radiation power of the object can be calculated according to the formula. Conversely, if the radiation power emitted by objects measured, can use the formula to determine the object surface temperature.

As we know, electrical equipment will be heating in normal operation, the process of the formation and development of electrical fault, the vast majority are related with heating. The user use electrical equipment in the process of conducting circuit part, the presence of a large number of joints, the contact or connection, if the conductive loop connection failure can be caused by the contact resistance is too large, when the load current through, will inevitably lead to local overheating; if the insulation of electrical equipment aging or damaged, will cause insulation dielectric loss is too large and in the operating voltage of the role, will produce overheating; in addition, optionally installed electrical equipment, also can make the conductor ampacity is too large to overheat, these overheated office has become the hidden danger of electrical fire.

2 infrared detecting instrument

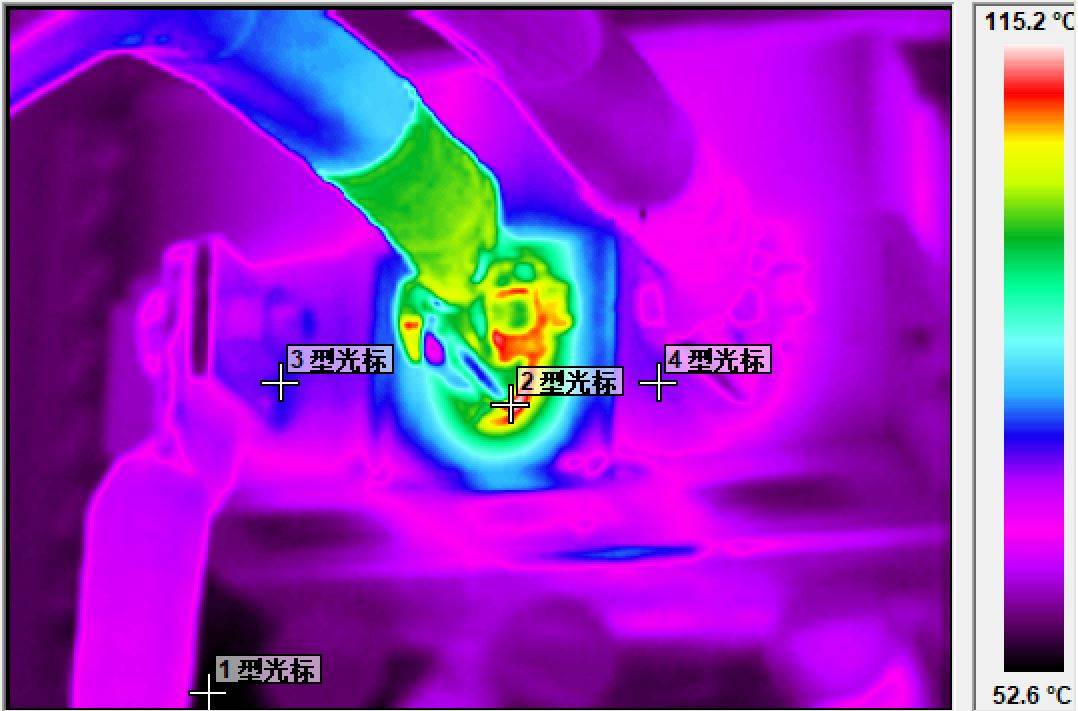

Infrared radiation energy of the infrared detection equipment can detect the overheating hidden fire emit, and convert it into a corresponding electrical signal, through the electrical signal processing system specialized for processing, finally by the imaging device to obtain thermal map should be relatively and surface temperature of the object, determine the hot spot location and temperature. This is the infrared detection technology of electrical fire hazard detection basis.

Infrared detecting instrument is varied, commonly used at present in our country fire protection work has three kinds, namely infrared thermometer, infrared thermal television, infrared thermal imager.

Detection and judgment of 3 electric fire hazard

Detection of infrared detection technology is mainly used in overheating fire hazards and determination.

Detection of 3.1 electrical fire hazards

Electrical fire hazard detection process is generally four steps:

(1) of electrical equipment and wiring general to conduct a comprehensive scan widely examined using infrared thermal television or thermal imager, found that the abnormal heating parts. The heating position intake thermography focus on electric equipment and line;

(2) for temperature measurement of abnormal heating parts by infrared thermometer. Temperature, should first correct choice of the measured object surface emissivity, select the appropriate reference to determine the environmental temperature, environmental temperature, relative humidity and type a measurement distance compensation parameter and select the appropriate temperature range;

To the same measuring object from different orientations were measured to find the highest hot temperature value, measuring the temperature of the measurement object different should keep distance uniformity and range;

(3) the actual surface temperature record abnormal heating electrical equipment load current, heating parts and ambient temperature;

(4) on the thermal images of the temperature field by computer analysis and processing.

Method to determine the 3.2 electrical fire hazards

3.2.1 temperature judgment method

According to the surface temperature of the heating position of electrical device of infrared thermometer measured, meanwhile considering the load rate and the connection part of the contact resistance of the electrical fire, the analysis of possible existence of hidden dangers.

This method is put forward to eliminate the necessary effect of different load and environmental temperature on the infrared judgment result of the. When the ambient temperature is low, especially the load current is small, the temperature of equipment value does not exceed the standard, but a large number of facts prove this when the temperature does not mean that the device has no defect or fault exists, often in the load growth, or the environment temperature rises, it will lead to the accident of the equipment, the formation of electrical fire hazard. So the current type of equipment can also be to determine the existence of hidden or not by adopting relative temperature difference method.

"The relative temperature difference" refers to the status of the equipment the same or substantially the same (of equipment type, installation location, environment temperature, surface condition and the load current and so on) the measured temperature difference between two corresponding points, and the ratio among the more heat measuring point temperature rise, the mathematical expressions for the

Δτ(%)=(τ2-τ1)/τ1×100(%)(3)

其中:

τ2——(°C); The higher the temperature measuring point temperature rise

τ1——(°C)。 The low temperature measuring point temperature rise

Usually, when the Δτ≥35%, can diagnose the equipment defects, should be tracking and monitoring, when necessary to plan maintenance.

3.2.3 similar comparative method

The same comparison is a comparison between similar devices, the so-called "similar" equipment refers to three of the same type equipment with a loop and the same device, i.e., their condition of same temperature than the same type equipment, are usually called "longitudinal comparison and transverse comparison" "". Specific approach is to similar equipment in the corresponding part of the temperature values are compared, it is relatively easy to determine whether the device is normal. In comparing like with like, should be careful not to rule out the possibility that the three-phase equipment also produces thermal fault, although the incidence rate is very low. The scope of application of similar comparative method widely, including the current type and voltage type equipment, including diagnosis of internal and external fault.

4 Conclusion

Infrared detection technology has many advantages, such as: test does not contact the electric equipment, do not influence ordinary work, can accurately and visually display the location and severity of electrical fire hazard, and can carry on analysis of computer science to make electrical fire hidden trouble diagnosis conclusion, and has the advantages of simple operation, fast detection speed and high working efficiency, strong safety detection, can keep a safe distance from electrical equipment, wide application range, can be used for various types of electrical equipment and power distribution line inspection. However, because the infrared detection instrument are surface temperature, and electrical equipment internal temperature because of the complex structure can not be accurately measured, so it must be combined with other measurement technology and scientific methods to better play its role. In addition, infrared detection technology is mainly for the detection of fire hazards to overheat, electric spark type electric fire hazard should adopt the ultrasonic detection.

Infrared detection technology has now developed into a high-profile high-tech, along with the social production and life of the modernization process accelerated, as a means of detection of electrical fire indispensable, infrared detection technology will be used more widely.

Infrared detection technology is based on infrared physics, infraredOptoelectronics and electronic computers are an emerging comprehensive technology developed on the basis of electricity, which is widely used in military, metallurgy, electric power, petrochemical, medicine and other fields. In recent years, remarkable results have been achieved in electrical fire safety testing, discovering electrical fire hazards, and preventing and reducing electrical fire accidents.

1 The principle

of infrared detection technology Infrared is an electromagnetic wave, its wavelength range is 0.76~1000μm, which is not visible to the naked eye. Any object with a temperature above absolute zero (-273.15°C) will constantly emit infrared radiation. According to Stephan-Boltzmann's law, the radiant power emitted per unit area of an object with temperature T is

P=εσT4 (1)

where:

P——radiant power per unit area, (W);

ε – surface emissivity of the object;

σ – Stephan-Boltzmann constant, whose value is 5.673×10-8W/(m2K4);

T – surface temperature of the object, (K).

From the above equation, it can be seen that the higher the surface temperature of the object, the greater the radiant power per unit area. When the surface temperature of the object and its emissivity are known, the radiant power of the object can be calculated according to the above equation. Conversely, if the radiant power emitted by an object is measured, the temperature of the surface of the object can be determined using the above equation.

We know that electrical equipment will heat up during normal operation, and the process of the formation and development of electrical faults is mostly related to heat up. In the process of using electrical equipment by users, there are a large number of joints, contacts or connectors in the conductive circuit part, if the connection of the conductive circuit fails, the contact resistance will be too large, and when the load current passes, it will inevitably lead to local overheating; If the insulation layer of electrical equipment is aging or damaged, it will cause excessive loss of insulating medium, and under the action of operating voltage, overheating will be generated; In addition, the random installation of electrical equipment will also make the conductor overheat due to excessive current carrying capacity, and these overheating places will become a hidden danger of electrical fire.

2 Infrared Detection Instrument The

red detection instrument can detect the infrared emitted by this overheated fire hazardRadiate energy and convert it into corresponding electrical signals, which are processed by a special electrical signal processing system, and finally obtained a thermal image corresponding to the surface temperature of the object through the imaging device to determine the location and temperature of the hot spot. This is the basis for infrared detection technology to detect electrical fire hazards.

There are a variety of infrared detection instruments, and there are three types of commonly used in China's fire protection work, namely infrared thermometer, infrared thermal TV, Thermal imaging cameras.

'

3 Detection and judgment methods

of electrical fire hazards Infrared detection technology is mainly used in the detection and judgment of overheating fire hazards.

3.1 Detection of electrical fire hazards The detection process of

electrical fire hazards is generally four steps:

(1) Use infrared thermal televisionsOr the thermal imaging camera will conduct a comprehensive scan of the general electrical equipment and circuits to find the abnormal heating parts. Thermal image acquisition of heating parts of key electrical equipment and lines;

(2) Use an infrared thermometer to measure the temperature of the abnormal heating part. When measuring temperature, the surface emissivity of the measured object should be correctly selected first, and the ambient temperature should be determined by selecting the appropriate reference object. Compensating parameters such as relative humidity and measuring distance and selecting the appropriate temperature range;

The temperature value of the highest hot spot should be measured from different directions for the same measurement object, and the distance and direction should be consistent when measuring the temperature of different measurement objects;

(3) Record the actual load current, surface temperature and ambient temperature of the abnormal heating electrical equipment;

(4) The temperature field of the thermal image is analyzed and processed by computer.

3.2 Methods for determining electrical fire hazards

3.2.1 Temperature judgment method

According to the surface temperature of the heating part of the electrical device measured by the infrared thermometer, At the same time, considering the load factor and the contact resistance of the connection part, the possible electrical fire hazard is analyzed.

Necessary This method is to exclude the load and the ambient temperature is different when the infraredJudgment on the impact of the results. When the ambient temperature is low, especially when the load current is small, the temperature value of the equipment does not exceed the specification standard, but a large number of facts prove that the temperature value at this time does not indicate that the equipment has no defects or faults. Therefore, the "relative temperature difference" method can also be used to determine the existence of hidden dangers for current equipment.

"Relative temperature difference" refers to the temperature difference between two corresponding measurement points in the same or basically the same condition (referring to the equipment model, installation location, ambient temperature, surface condition and load current, etc.), and the ratio of the temperature rise of the hotter measurement point, and its mathematical expression is

Δτ(%)=(τ2-τ1)/τ1×100(%)(3)

Where:

τ1 - the temperature rise of the higher temperature measurement point ,(℃);

τ2 - the temperature rise at the lower temperature measurement point, (°C).

Usually, when Δτ ≥ 35%, the defect of the equipment can be diagnosed, and it should be tracked and monitored, and planned maintenance should be arranged if necessary.

3.2.3 Like-for-like comparison

The meaning of the so-called "similar" equipment refers to the same type of equipment in the same circuit and the three phases of the same equipment, that is, the same type of equipment when their working conditions and ambient temperatures are the same and comparable, which is usually called "longitudinal comparison" and "horizontal comparison". The specific method is to compare the temperature value of the corresponding part of the same type of equipment, and it is relatively easy to judge whether the equipment is normal. When making like-for-like comparisons, it is important to note that the possibility of simultaneous thermal failure of a three-phase device cannot be ruled out, although the probability of this occurring is quite low. Like-for-like comparison methods can be applied to a wide range of applications, including current and voltage equipment, as well as the diagnosis of internal and external faults.

4. Conclusion

Infrared detection technologyIt has many advantages, such as: do not contact the electrical equipment during the test, do not affect the normal work of the inspected unit, can accurately and intuitively display the location and severity of the electrical fire hazard, and can carry out computer analysis, scientifically make the diagnosis conclusion of the electrical fire hazard, and has the easy operation, fast detection speed, high work efficiency, strong safety, can keep a safe distance from the electrical equipment during the detection, has a wide range of applications, can be used for the inspection of various types of electrical equipment and distribution lines, etc. However, because infrared detection instruments measure the surface temperature of objects, and the temperature inside electrical equipment cannot be accurately measured due to complex structure, it must be combined with other measurement technologies and scientific methods to better play its role. In addition, infrared detection technology is mainly aimed at the detection of overheating fire hazards, and ultrasonic detection should be adopted for electric spark electrical fire hazards.

Infrared detection technology has developed into a high-tech that has attracted much attention, with the acceleration of the modernization process of social production and life, as an indispensable means of detection of electrical fire prevention, infrared detection technologyIt will be more widely used.